Aligning the “Useful” and “Environmental” Lifetime of Plastics: Elijah Martin’s Engineering Challenge

Design fellows

Elijah Martin, a second-year PhD student in the Department of Civil and Environmental Engineering, and a design fellow at the MIT Morningside Academy for Design (MAD), created a photo weathering method that accelerates plastic degradation research. With the help of Elijah’s prototype, plastics that align useful and environmental lifetimes could be developed, significantly reducing the harmful impact of plastic pollution on our planet.

By Adelaide Zollinger

Aug 7, 2023

The word “plastic” comes from ancient Greek “plastikos,” meaning: “capable of being shaped or molded,” and was originally used to describe substances that could be easily formed into various shapes. In the mid-19th century, the term started to acquire its modern sense, with the invention of the first human-made plastics, such as Parkesine and celluloid, respectively invented by British chemist Alexander Parkes, and American inventor John Wesley Hyatt. Since then, the term has evolved to encompass a wide range of synthetic materials with unparalleled convenience and versatility.

As such, plastics have become an integral part of our lives, pervading almost every aspect of our daily routines, from the packaging that safeguards groceries to the sturdy materials that construct homes. In recent years, the global production of plastics has skyrocketed to unprecedented levels, with a staggering 460 million tons according to a 2019 study published by the OECD. What’s more: “The world is producing twice as much plastic waste as two decades ago, with the bulk of it ending up in landfill, incinerated or leaking into the environment, and only 9% successfully recycled,” the same source concludes.

Elijah Martin, in his CEE lab.

Photo: Adelaide Zollinger

Plastics’ ubiquity is attributed to the material's low cost, durability, and diverse range of applications, which makes it difficult to replace on a large scale. But their proliferation poses a serious threat to our ecosystems because of their persistent nature. As we grapple with the urgent need to address plastic pollution, researchers like Elijah Martin, a second-year PhD student in the Department of Civil and Environmental Engineering at MIT, and a design fellow at the MIT Morningside Academy for Design (MAD), are delving into the strategic domain of plastic degradation to unlock sustainable alternatives.

The study of “plastic degradation,” ie, how plastics break down over time, plays a tactical role in answering compelling questions such as how fast and how safely different plastics degrade in a variety of environments. It involves various testing methods, like accelerated weathering, soil burial tests, and marine simulations. In one of MIT's state-of-the-art labs, Elijah, an ex-Beyond Meat engineer, translated his passion for environmental sustainability into a new kind of photo weathering method to observe chemical changes and photodegradability rates more effectively.

Plastics are usually used between a week — or even less — to a few years, whereas they can take hundreds to thousands of years to degrade, and meanwhile, are harmful to people and wildlife. Elijah explains:

If successful, Elijah’s research will provide a novel framework for designing plastics that degrade effectively, offering a solution to the growing plastic waste problem while maintaining the convenience we've grown accustomed to.

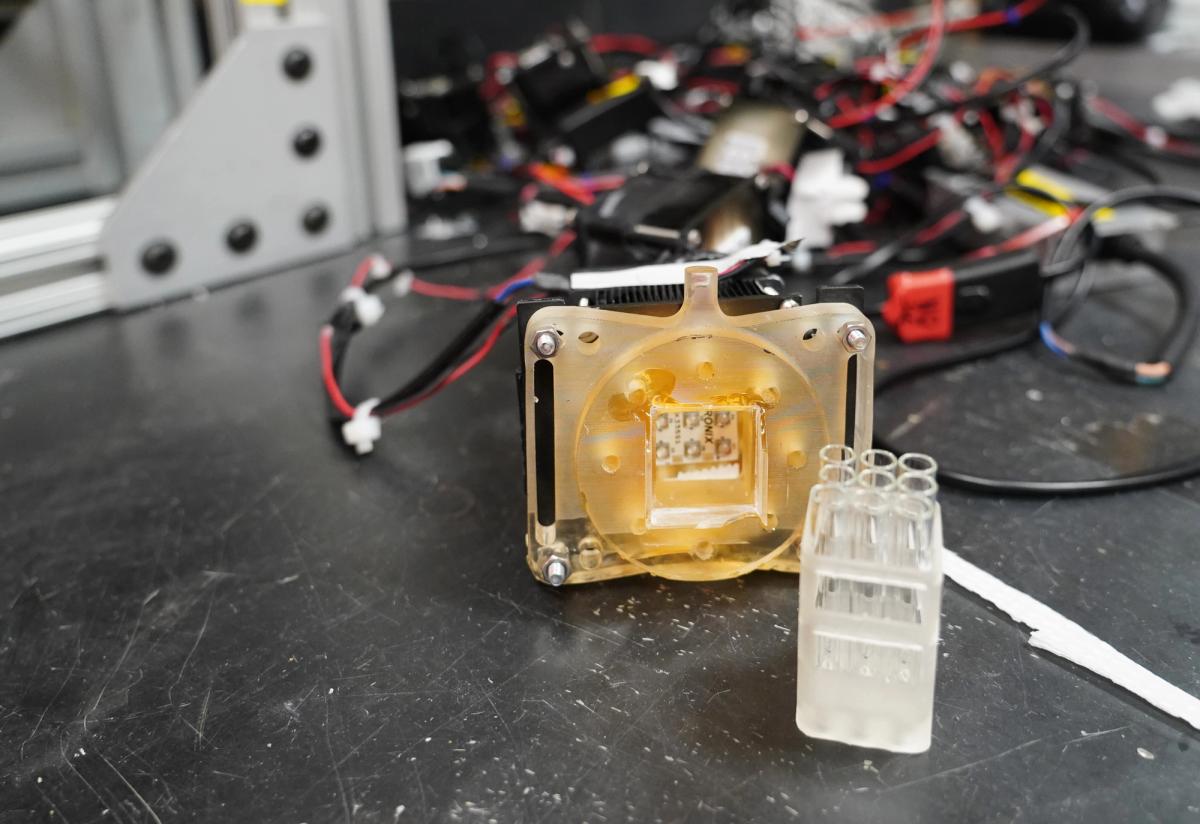

Conventional large-scale solar simulators create “a spectral match which is supposed to mimic what the sun creates in terms of light power and wavelength,” Elijah continues. However, this kind of equipment takes up a lot of space and produces results over a long period of time. In the lab, Elijah’s ambition has been to design a much more compact, modular, and faster photo weathering method, harnessing the power of UV LEDs to simulate sunlight and induce plastic degradation. His prototype — created from parts he 3D-printed in MIT makerspaces, small glass tubes, and UV LED lights directly above them — is paving the way for rapid and efficient data collection, offering simplified yet scalable simulations of environmental conditions.

Elijah Martin's prototype.

Photo: Adelaide Zollinger

Tubes are filled with various plastic types immersed in water and exposed to controlled wavelengths of UV light, allowing Elijah to evaluate degradation rates and to understand the key factors influencing the process. In his work, he started by examining main commodity plastics commonly seen in recycling logos: polyethylene terephthalate (PET), polypropylene (PP), low-density polyethylene (LDPE), high-density polyethylene (HDPE), PVC, and polystyrene. His objective is now to test niche plastics and look more specifically into how modifying a particular chemical functional group could improve degradability. This valuable data could in turn be used by polymer chemists to achieve far-reaching implications for industry and consumers alike.

The journey to revolutionizing sustainable plastics is not without its challenges. One of the primary obstacles Elijah faces is sourcing reliable and consistent UV LED components. Ensuring that plastics experience the same light exposure during testing is crucial to obtaining accurate and meaningful data. Additionally, quantifying the degradation rates and establishing precise parameters for the photo weathering process demand rigorous and ongoing investigation.

Elijah Martin, demonstrating his photoweathering prototype.

Reflecting on some of the resources he’s found helpful throughout the past year, Elijah remarks:

”The fellowship also gave me more flexibility in getting my prototype up and working and generating data, which has been really cool to see. The financial support allowed me to be more independent in my goals, which was huge,” he adds.

Design fellows weekly lunch seminar.

Noting that “from a climate perspective, many applications of plastics are much better than other alternatives such as metals or glass,” Elijah hopes that combining innovative methodologies with the latest scientific understanding will shift how plastics impact the environment. “The plastic problem and other environmental problems can seem disparate, but they’re actually tightly linked. […] I feel like we haven't even started to address this growing plastic waste problem; there is so much that needs to be done. That's what motivates me to work on this,” he concludes.